Floor Smoothing and Leveling

What do we need?

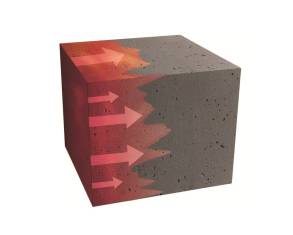

For application of parquet, carpet , plastic tiles ( PVC ) epoxy floors or other applications , required horizontal floors, completely flat and smooth. With concrete and common screed it is impossible to achieve the desired results .

How do we do it?

On the floor we will apply the self-leveling mortar NSF 610 for smoothing to 10mm or NSF 611 for smoothing larger defects 1- 4cm. The floor will have a smooth surface and it is ready to be coated with the ingredients of your choice.

Products used

GLX 290

NSD 600

NSF 610

NSF 611

Step by step

- Initially we provide powerful and clean surfaces without cracks and gaps.

- If floors have large gaps greater than 4cm (ie the maximum application thickness of NSF 611) even and locally, we first apply the cement NSD 600 (see. Filling floors with cement mortar) in order to smooth the surface.

- Prime the cement with the acrylic primer GLX 290 diluted at a ratio GLX 290 to water = 1: 3. After 2 to 6 hours depending on atmospheric conditions may make the application of the cement. For smoothing to 10mm select the leveling mortar NSF 610 while smoothing between 1cm to 4cm select NSF 611.

- Prepare leveling floor giving great care to use exactly the amount of water indicated on the bag or in the technical leaflets of the company. For the preparation can be used manual electric low speed mixer or continuous mixer which necessarily must have special accessories for self-leveling floors. The finished product is cast and is assisted by a large toothed metal spatula etc. In order to cover the desired surface. While the floor is still fluid, we process the surface with special radial roller, to release any trapped air. This way they will avoid joints between the different layers and result in a uniform and leveled surface. Recommended to use drivers to achieve uniform thickness. To avoid occurrence of cracks developed in the substrate recommend the use of expansion joints. If prevailing conditions causing abrupt drying of the product, such as heat, light spraying with water required for the first two days after application. Allow the product to dry completely before the next application. This duration will depend on the climatic conditions. But proposed time is about 15 days. During the application and for the next 24 hours the temperature of the ambient and substrate should be between + 5 ° C and + 35 ° C.

Product Categories : Chapes