Filling with Lightweight Screed

What do we need?

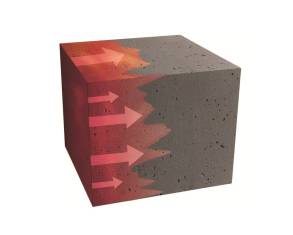

Before laying the tiles on floors, surfaces have to be flat and relatively smooth. Usually required thick leveling material in order to smooth the surfaces to provide the necessary slopes for removal of the water and additionally fill tubes plumbing, heating, etc. that are placed on the ground. This large material thickness burden plates of the building with large loads.

How do we do it?

For leveling of floors and covering of pipes will be used lightweight, thermal insulating floor screed NSD 620 which consists of grains form from crushed AAC (YTONG).

Products used

GLX 290

GLX 296

NSD 620

Step by step

- Clean the floors from dirt and concrete residues. Fill – if any – large gaps.

- Place a foam material 1cm thick to the perimeter wall so the cement will fall not to touch the walls.

- Prime the substrate with acrylic primer GLX 290 diluted at a ratio GLX 290 to water = 1: 3. After 2 to 6 hours depending on atmospheric conditions may do the application of the screed.

- Place appropriate drivers, in order to ensure the slopes and leveling of finish. Prepare the mortar by machine and by hand and spread on floor with the help of common metal cubit or vibrating.

- For best results, strength, elasticity, adhesion recommend in mixing water to be added and an amount of improver admixture GLX 296.

- When screed ‘pull’, depending on the size of the surface create expansion joints per 2.5-3 current meters to reduce contractions and creating cracks.

- For applications that do not have direct bonding of the screed to the background (such as on polythene sheeting, insulation boards, etc.) requires appropriate support to reinforce. The floor is passable after 12 hours at + 20 ° C.

- If prevailing conditions causing abrupt drying of the product, such as heat, light spraying with water required for the first two days after application.

Product Categories : Chapes